An Advance in BioFuel Production

I saw an interesting press release from UM today. According to it:

University of Maryland research that started with bacteria from the Chesapeake Bay has led to a process that may be able to convert large volumes of all kinds of plant products, from leftover brewer's mash to paper trash, into ethanol and other biofuel alternatives to gasoline.

University of Maryland research that started with bacteria from the Chesapeake Bay has led to a process that may be able to convert large volumes of all kinds of plant products, from leftover brewer's mash to paper trash, into ethanol and other biofuel alternatives to gasoline.

That's pretty exciting since, if commercially viable, it'll allow "cheap" plant materials to be used to produce ethanol. Using corn, as we do now, is silly since the energy you get out isn't much higher than what you put in to grow and process the corn.

And then there's the really annoying side effect of raising prices to consumers on corn and all downstream products (farmland, cows, meat, soda, popcorn, and on and on and on---everything uses corn!). Making ethanol from switchgrass won't cause these economic difficulties.

That process of making ethanol from cellulose was developed by University of Maryland professors Steve Hutcheson and Ron Weiner. They're professors of cell biology and molecular genetics and have formed the incubator company Zymetis to develop the technology.

University of Maryland research that started with bacteria from the Chesapeake Bay has led to a process that may be able to convert large volumes of all kinds of plant products, from leftover brewer's mash to paper trash, into ethanol and other biofuel alternatives to gasoline.

University of Maryland research that started with bacteria from the Chesapeake Bay has led to a process that may be able to convert large volumes of all kinds of plant products, from leftover brewer's mash to paper trash, into ethanol and other biofuel alternatives to gasoline.That's pretty exciting since, if commercially viable, it'll allow "cheap" plant materials to be used to produce ethanol. Using corn, as we do now, is silly since the energy you get out isn't much higher than what you put in to grow and process the corn.

And then there's the really annoying side effect of raising prices to consumers on corn and all downstream products (farmland, cows, meat, soda, popcorn, and on and on and on---everything uses corn!). Making ethanol from switchgrass won't cause these economic difficulties.

That process of making ethanol from cellulose was developed by University of Maryland professors Steve Hutcheson and Ron Weiner. They're professors of cell biology and molecular genetics and have formed the incubator company Zymetis to develop the technology.

"The new Zymetis technology is a win for the State of Maryland , for the University and for the environment," said University of Maryland President C.D. Mote, Jr. "It makes affordable ethanol production a reality and makes it from waste materials, which benefits everyone and supports the green-friendly goal of carbon-neutrality.

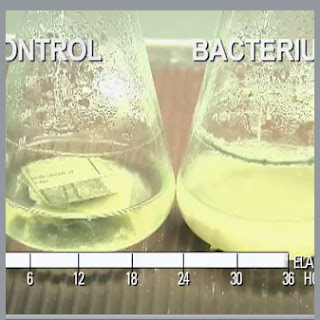

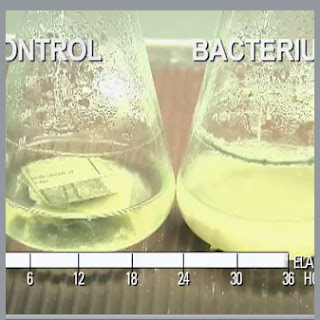

The UM site has a video of the bacterial process. Click here to see the Zymetis process.

The Zymetis process can make ethanol and other biofuels from many different types of plants and plant waste called cellulosic sources. Cellulosic biofuels can be made from non- grain plant sources such as waste paper, brewing byproducts, leftover agriculture products, including straw, corncobs and husks, and energy crops such as switchgrass.

When fully operational, the Zymetis process could potentially lead to the production of 75 billion gallons a year of carbon-neutral ethanol.

The secret to the Zymetis process is a Chesapeake Bay marsh grass bacterium, S. degradans. Hutcheson found that the bacterium has an enzyme that could quickly break down plant materials into sugar, which can then be converted to biofuel.

The UM site has a video of the bacterial process. Click here to see the Zymetis process.

The Zymetis process can make ethanol and other biofuels from many different types of plants and plant waste called cellulosic sources. Cellulosic biofuels can be made from non- grain plant sources such as waste paper, brewing byproducts, leftover agriculture products, including straw, corncobs and husks, and energy crops such as switchgrass.

When fully operational, the Zymetis process could potentially lead to the production of 75 billion gallons a year of carbon-neutral ethanol.

The secret to the Zymetis process is a Chesapeake Bay marsh grass bacterium, S. degradans. Hutcheson found that the bacterium has an enzyme that could quickly break down plant materials into sugar, which can then be converted to biofuel.

Comments